PLA Iron-filled ( Metal Composite ) 50g ( Amostra ) – ProtoPasta

Outros makers também compraram..

Produtos testados e aprovados pela nossa comunidade. Se eles confiam, tu também podes confiar.

ProtoPasta é uma empresa situada nos Estados Unidos da América, de produção de filamentos para impressão 3D de alta qualidade.

Caracterizada pelos rolos feitos em cartão, esta marca é mundialmente famosa por ser especializada em materiais como PLA e ABS modificados com outros materiais, como o PLA Magnético; o PLA Condutivo; PLA de fibra de carbono; HTPLA de cobre, latão ou bronze; ou o ABS-PC.

Prints like PLA, behaves like metal! Experience our most “attractive” material yet!!!

Protopasta Rustable Magnetic Iron Metal PLA Composite is actually ferromagnetic.

It responds to magnets and behaves similarly to pure iron! Encapsulated in plastic, the iron maintains a stable matte, cast metal finish as printed, but can be rusted when desired.

More product specific details and application ideas for our Rustable Magnetic Iron Metal PLA Composite can be found below.

Prints like PLA, behaves like metal! Experience our most “attractive” material yet!!!

Proto-pasta Rustable Magnetic Iron Metal PLA Composite is actually ferromagnetic. It responds to magnets and behaves similarly to pure iron! Encapsulated in plastic, the iron maintains a stable matte, cast metal finish as printed, but can be rusted when desired. Here is why Proto-pasta Iron PLA is so interesting:

- Weighted feel with 1.5x the density of standard PLA

- Rustable to create modern artifacts in a few easy steps – instruction here

- Attracts magnets (neodymium type recommended for strongest attraction)

- Induction at magnetic saturation about 0.15 Tesla

- Relative (to air) Permeability – between 5 and 8 independent of frequency up to 1 MHz

- Permeability – between 62E-7 and 100E-7 H/m independent of frequency up to 1 MHz

- More thermally conductive than standard plastic

- Prints easily like PLA with less nozzle wear than Steel or Carbon Fiber

- More filament for your money – 2x the length of Bronzefill (50g Iron =50g Bronzefill)

We recommend experimenting with creating a rusty patina like this:

**This filament is more abrasive than standard PLA. Be prepared to replace your nozzle and do 1st layer adjustment. Try a wear resistant and/or larger diameter nozzle for increased service intervals.

- Available in 1.75 & 2.85 (3) mm diameters.

- 125g are loose coils, 50g is on a 8″ diameter spool, 2kg is on a 12″ diameter spool.

- Usable on most PLA-compatible printers, such as Lulzbot, Makerbot, FlashForge, Dremel, Ultimaker, Printrbot, and more!

In filament form, FEPLA is slightly more brittle than standard PLA, and requires extra care when handling.

Processing is comparable to standard PLA. No heated bed required. Process may be less consistent on smaller nozzles and/or bowden type machines. We frequently print using direct-drive systems with 0.4 mm nozzles, though prefer 0.6 mm and 190-210C (standard PLA or a bit cooler) for the best experience.

CHARACTERISTICS

- Weighted feel with 1.5x the density of standard PLA

- Rustable to create modern artifacts in a few easy steps – instruction here

- Attracts magnets (neodymium type recommended for strongest attraction)

- Induction at magnetic saturation about 0.15 Tesla

- Relative (to air) Permeability – between 5 and 8 independent of frequency up to 1 MHz

- Permeability – between 62E-7 and 100E-7 H/m independent of frequency up to 1 MHz

- More thermally conductive than standard plastic

- Prints easily like PLA with less nozzle wear than Steel or Carbon Fiber

- More filament for your money – 2x the length of Bronzefill (50g Iron =50g Bronzefill)

APPLICATIONS

- Faux brick or stone

- Fixtures or hardware

- Knobs or buttons

- Heat sinks or exchangers

- Fine art & sculpture

- Emblems, signage, or trophies

- Jewelry, like pendants or bracelets

- Cosplay, game pieces, or figurines

MATERIAL DATA

- Base resin: PLA

- Additive: Real Iron Powder

- Particle size: less than 250 micron (0.25mm)

- Odor: low or no

- Density: Approx. 1.85 g/cc

- Length (50g): 97m (1.75mm) and 36m (2.85mm)

PRINTER SETTINGS

- Speed: 10-20 mm/s 1st layer, 20-80 mm/s rest of part

- Nozzle Set-point: 185-215C (hottest on 1st layer for best adhesion)

- Nozzle Actual: maintain set-point, reduce speed if less than

- Nozzle Type: Standard or wear resistant for extended use

- Nozzle Diameter: 0.6mm or larger preferred, 0.4mm okay with 0.25mm minimum for experts

- Layer thickness: 0.15-0.20mm recommended for a balance of quality, reliability, and productivity

- Bed Temperature: Room-60C (over 60C can worsen warp)

- Bed Preparation: Elmers purple disappearing glue stick or your other favorite PLA surface preparation

This material has been flow optimized and has less moisture uptake than standard PLAs, however composites are still sometimes more tricky to print depending on hardware and software settings. The main challenge is to keep mass flow up (larger nozzle + fast speed) and in a single direction (minimal retraction) to avoid heat soak.

Getting Started with Proto-pasta PLAs including HTPLA

We’ve created this page to bring you a premium PLA and HTPLA printing experience that rivals our premium material. Follow below to improve your 3D printing experience. In other words, here’s your shortcut to awesomeness with pasta. If at the end of this document you have questions or need assistance, please contact us at support@protoplant.com.

Filament Handling

Loose coils can be very tricky to manage. Going cowboy on your spool handling can quickly end up in a frustrating, tangled mess. Keep your loose coils wrangled with a spool holder like masterspool for a more trouble-free experience. Find out more about loose coil handling in Keith’s blog post.

And for spooled filament, never let go of the loose end. When not in the printer extruder, tuck it away in the cardboard spool’s corrugation! Also, avoid sharp bends and excessive force when loading filament into your printer.

Print settings

At Proto-pasta, we make high quality filament. We aspire to make exceptional results easy, but a positive result is very much dependent on your hardware, set-up, adjustments, and process parameters. Matching hardware with process and material for a positive experience is not always straight-forward, but you can start by pairing the following settings with your printer for a good starting point, then tune or troubleshoot as required.

Example settings for typical printer

- Nozzle size = 0.4 mm (Standard to most printers & balances detail with productivity.)

- Extrusion width = 0.45 mm (Typically larger than nozzle size. If using a larger nozzle diameter, be sure to set the extrusion width larger than that nozzle diameter.)

- Layer thickness = 0.15 mm (For a balance of speed, quality & reliability.)

- Speed(s) = 15-45 mm/s (Respecting mechanical and volume flow limits. Stay within the recommended speed range but apply slower speeds to the walls and faster speeds to the infill.)

- Volume flow rate(s) = 1-3 cu mm/s (The result of above speed range, width, and layer thickness. Respect hardware and geometry limitations.)

- Typical temperature = 215 C +/- 10 C (Matching material, hardware, and volume flow rate.)

Volume flow rate together with temperature dictates how melted the material is. This is hardware & condition dependent based on hot end, nozzle & extruder type, material & manufacturer as well as layer fan type, position & settings. Extrusion width, layer thickness & speed changes affect volume flow which may change required/desired temperature.

Additional settings of note

- “Grid” infill type at 20-30% – “connect infill lines” unchecked (off).

- Minimum 3 shells & 4 top/bottom layers for good surface quality.

- Layer fan set to cool enough for build rate, but not so aggressive as to fail process by over-cooling nozzle and heater block.

Validation and fine-tuning

- Single wall box to tune temperature and extrusion-related settings.

- Protognome to validate results.

Post your prints & tag us @Proto_pasta on Twitter and Instagram. Need more help? Consider typical pitfalls and fixes below.

Typical pitfalls

- Exceeding hardware capabilities.

- Mismatch of flow rate and temperature.

- Excessive nozzle cooling from layer fan yielding lower heater block and/or nozzle temperatures than set point.

- Hardware shortcomings such as MK3 heat break, poor nozzle diameter, or other hangups.

- Poor assembly or adjustment of components.

- Excessive retraction distance or number of retractions.

- Inaccurate flow with missing cross-sections or wall thickness not matching extrusion width software setting.

Typical Fixes

- Heat break replacement with OEM, straight-through design and defect-free, smooth bore.

- Proper assembly of components without plastic oozing gaps & with thermal grease.

- Lightly oiling filament, but careful, a little goes a long way.

- Reducing layer fan speed and/or isolating from heater block and nozzle.

- Installing heater block sock to isolate heater block & nozzle from layer fan.

- Increasing temperature to flow past internal hang-ups.

- Reduce speed and/or choose a single speed for a single volume flow

- Consider drive gear tension adjustment, bowden tube coupling/replacement, and spool mounting

We visited Joel and ended up with a helpful video on the subject:

Magnetic Iron PLA

Protopasta Magnetic Iron PLA – as its name implies – responds to magnets and behaves similarly to pure iron, even to the point of rusting! Magnetism opens up a new world of practical applications and fun creations, and is an especially great choice for costume pieces and props!

What is it made out of?

Protopasta Magnetic Iron PLA is a compound of Natureworks 4043D PLA and finely ground iron powder. In filament form, it is rather brittle, and should be handled with care to avoid breakage.

Magnetic vs. Ferromagnetic

Iron is defined as “magnetic” but it is, more accurately speaking, ferromagnetic. That means it is attracted to magnetic fields. In short, magnets stick to it. So, you should note that magnets stick to prints made from Magnetic Iron PLA, but printed objects will not function as magnets. We call our material “Magnetic Iron PLA” to communicate that this material allows users to include the added benefits of magnetism when designing and printing 3D objects.

Could I magnetize my finished prints?

We haven’t tested this ourselves, but it makes sense that thin prints could be magnetized by rubbing them 10-100 times across the positive side of a large magnet. Ferromagnets will tend to stay magnetized to some extent after being subjected to an external magnetic field due to a fascinating process called hysteresis. We will test this theory in a future blog post.

Permanent magnetism requires the use a strong electromagnetic coil (around 2 Tesla), but that process would melt your print, so as awesome as it sounds, don’t try it.

Is It Stronger?

No. The strength of Protopasta Magnetic Iron PLA is similar, and likely somewhat less, than the strength of standard PLA. The iron in the filament is too finely ground to provide an increase in overall strength.

Is it conductive?

No. The iron is too small and separated by the PLA to offer any noticeable amount of conductivity. You should try our Conductive PLA!

Rusting Magnetic Iron Prints

To rust a print made with Magnetic PLA, lightly abrade the surface of your print with a wire brush to expose more iron particles to the air, then submerge the print in a salty solution for 2-3 days (or longer, if you’re going for a very rusty look!).

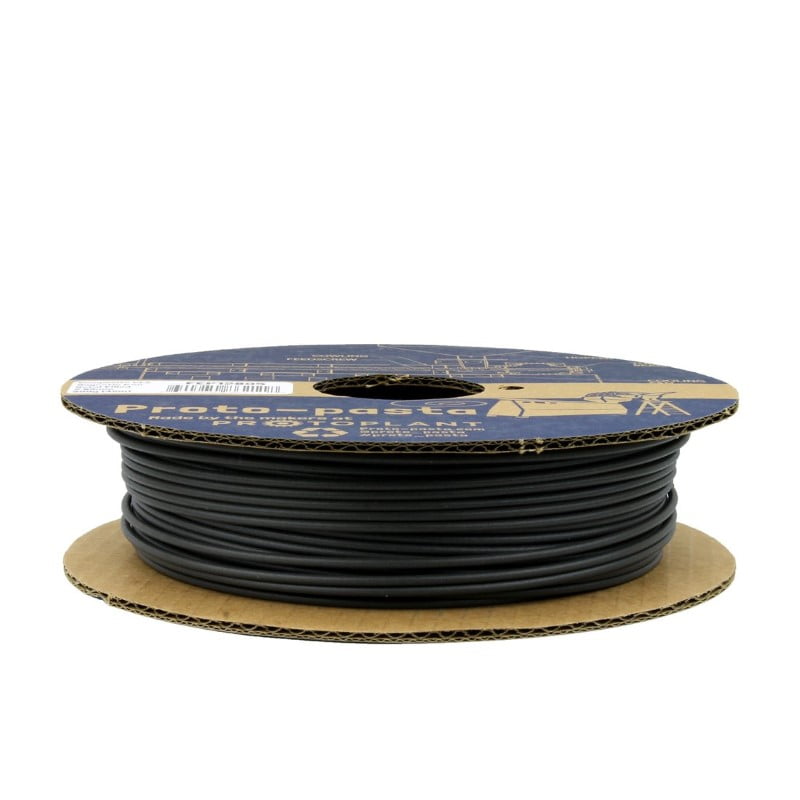

Spool Amount: Density vs. Length

3D printer filament is sold in grams /kg, even in the case of exotic materials with greater density. Our Magnetic Iron PLA is quite dense compared to standard PLA. As a result, a 500 g spool of Magnetic Iron PLA contains about 100 meters of filament, vs. nearly 200 meters on a 500 g spool of standard PLA.

Printer Settings

Protopasta Magnetic Iron PLA prints at similar temperatures as standard PLA, though we have found it seems to like it about 10 degrees cooler than what we usually print PLA at. Quick cooling seems to increase the tendency to warp, so you might try turning your fan off and slowing your printer down a bit. Experiment and see what work best with your machine.

Density:

1.8 g/cm3 (1800 kg/m3)

Parameters:

Bed Temp (if available, is not required): 50° C

Hot End Temp: 185– 195° C

Para uma correcta manutenção da sua impressora 3D, recomendamos sempre que trocar de material de filamento 3D, a efectuar uma purga com filamento especial de limpeza.

Desta forma garante que não ficam vestígios de material nas paredes do nozzle, evitando o acumular de crosta que é criado sempre que efectua trocas de material.

Com este produto evita problema como “clogs” e “jams” e fará com que o seu nozzle mantenha-se sempre limpo, durando muito mais tempo.

Poderá encontrar a partir de 1.49€ no seguinte LINK

Este material é altamente abrasivo. Recomendamos a utilização de Nozzles de aço endurecido.

Poderá encontrar no seguinte LINK

Para obter maior aderência à superfície da sua impressora 3D recomendamos a aplicar 3DLAC na base da plataforma.

Poderá encontrar no seguinte LINK

Este material é altamente higroscópico, absorvendo rapidamente a humidade do ar passados poucos minutos após aberto, impossibilitando desta forma a correcta impressão 3D do mesmo. O resultado das impressões 3D de materiais com humidade tendem a ser frágeis e de acabamento irregular ou em certos casos, torna-se simplesmente impossíveis de imprimir.

Deverá de usar soluções de caixas fechadas com dessecante como sílica ou caixas próprias secadoras de filamento.

Poderá encontrar no seguinte LINK

Download:

Technical and Safety Data Sheet

50g– Rolo

PLA Iron-filled ( Metal Composite ) – Cor

1.75mm (+-0.05mm) – Espessura / Tolerância de diâmetro

Fácil – Facilidade de Impressão

| REF: | 26472 |

|---|---|

| Categorias: | Impressão 3D, Filamentos 3D, PLA, Especiais |

| Etiquetas: | 3d, abrasivo, alta, amostra, amostras, best, Black, Composite, de, ferro, ferromagnetic, ferromagnetico, ferrugem, filamento, filled, fosco, High, HTPLA, impressao 3d, ingeo, iron, iron-filled, magnetic, magnetico, materials, melhor, metais, metal, natureworks, negro, Opaque, particles, pasta, pla, Premium, Preto, proto, proto-pasta, protopasta, qualidade, rolo, rust, rusty, sample, samples, sem brilho, temperatura, temperature |

| Marca: | ProtoPasta |

Outras opções que podem interessar-te

Impressoras 3D e produtos similares com características diferentes. Compara e escolhe o que melhor se adapta aos teus projetos.

Pré-reserva

Pré-reserva Envio 24H

Envio 24H Pré-reserva

Pré-reserva Envio 24H

Envio 24H Envio 24H

Envio 24H

Avaliações

Ainda não existem avaliações.